0%

Loading

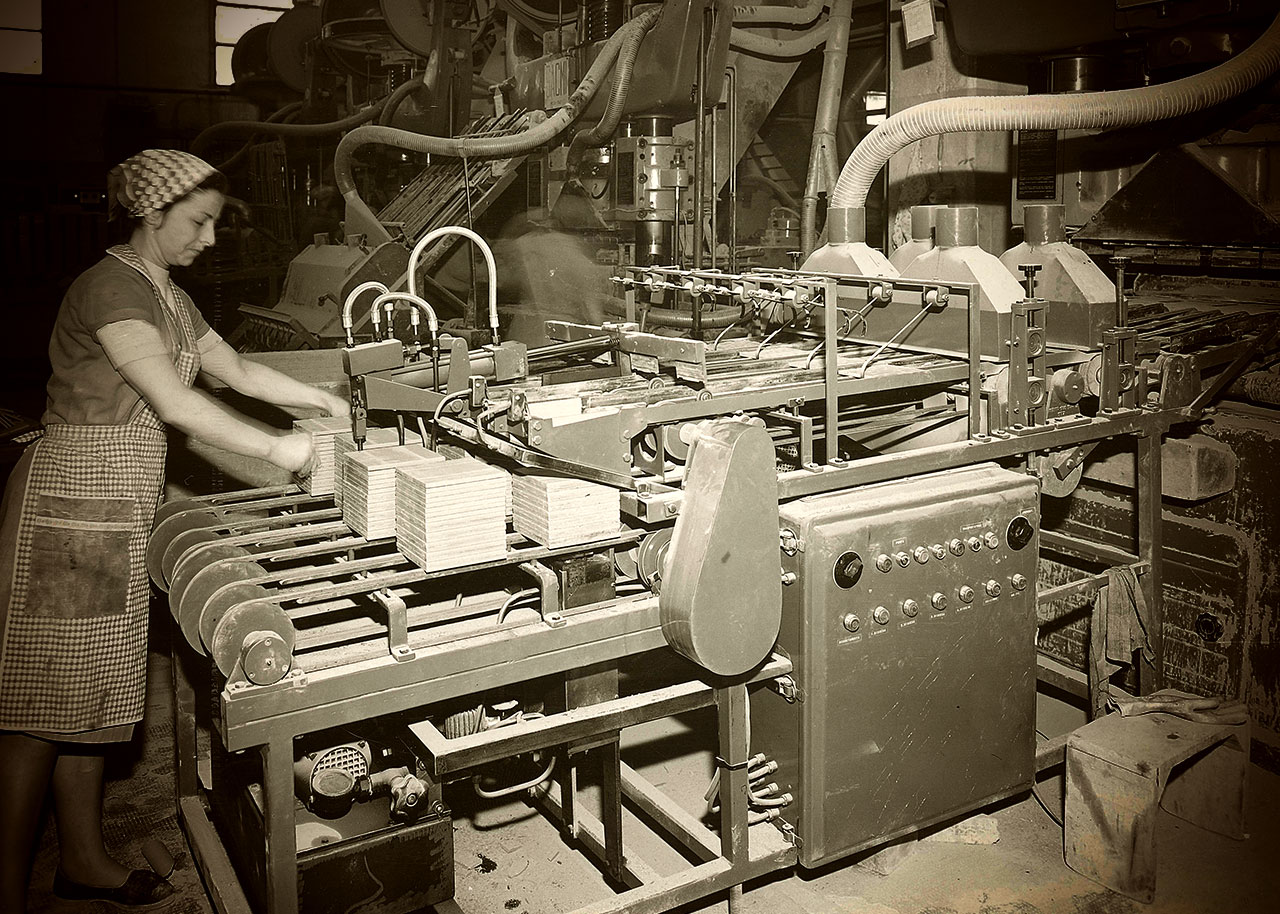

Historical Archive

The value of a flower

When Iris was first established in the Italian Ceramic Industry, precisely in 1961, it couldn’t be foreseen that just a symbol would have been essential to the development of the company and subsequently recognized as an important part of its brand values.

At first, the company needed a logo with a real significance and a meaningful name. From all the options and ideas that had emerged, the name “Iris” was definitely considered to be the perfect one because it recalls a flower called “Giaggiolo” (in Italian). In fact, “Iris” is a native type of flower from the shores of Tiepido’s creek in the Province of Modena where the moisturized soil can be already called “Clay”.

Another great inspiration to be considered is that the word “Iris” (in Greek) alludes to the “The goddess of the Rainbow”, and she is considered to be the the personification of the rainbow and the messenger of the gods. This goddess is an amazing young deity with incredible speed who delivers the messages coming from the sky. She is depicted wearing a coat of many colors, with this coat she creates the rainbows when she rides from place to place. Moreover, a rainbow is a spectrum of light that reflects seven colors together (red, orange, yellow, green, blue, indigo and violet) and these colors are essential to the development of ceramic products.

Also, in Florence there’s the a coat of arms called “Giglio di Firenze” in which the bloomed Iris in the coat represents people celebrating the spring season and all its colorful flowers.

In addition, Iris is also the name given to the colored, muscular ring around the pupil of the eye, located between the cornea and lens. This complex optical system, called eye, allows people to see and choose things.

Consequently, the combination of all these elements created a very strong brand concept. The next step was an acronym “Industria Rivestimenti Italiani Sassuolo” created from the word Iris, meaning “Italian Ceramic Industry in Sassuolo”. In fact, the company’s concept and acronym together have always been the best representation of our brand identity.

21st century

“Innovation is certainly the answer to these difficult times we are experiencing. We are witnessing epic changes, but I keep repeating the same answer”, said Romano Minozzi in the celebration for the 50 years from the foundation of Iris Ceramica. He continued: “The two main foundations of the ceramic industry are innovation and quality. We say that the quality has always been in our companies, and I still can remember the very first days when I organized the first project with Iris Ceramica's staff. After that, I have constantly insisted about the importance of quality combined with innovation of the products. I believe that nowadays one of these foundations is missing and therefore not standing properly in the ceramic industry in Italy, our area, our legacy, our roots. In my heart, the ceramic industry of Sassuolo is still essential to the world. Just within our group, we have at least 4 or 5 research laboratories and many researchers, who continue to experiment and search for ways to open up new horizons to our products. It’s crucial to our development to keep researching. As for Active Ceramic, this brand became our most technological and advanced product at the moment”. Romano Minozzi, Founder of Iris Ceramica

Establishement of Fondazione Iris Ceramica Group (2019)

Fondazione Iris Ceramica Group was established on the initiative of Romano Minozzi and his daughter Federica.

Fondazione Iris Ceramica Group is a non-profit organization intended to promote environmental protection, sustainable development and social cohesion. It supports projects aimed at developing new ways of bringing people together and achieving collective well-being, and the dissemination of ethical guidelines for companies and people.

Zero Emission

In March 2019 the Group announced achievement of zero impact production, an ambitious goal confirming the Group’s desire to reconcile industrial production with human well-being. The project, which required investment of considerable funds, gave the Castellarano production site three combustion plants with regenerative heat recovery capable of guaranteeing ultra-high efficiency eliminating the volatile organic molecules present in flue gases, including odours.

IRIS CERAMICA GROUP OPENS THE DOORS TO ITS HISTORICAL MUSEUM

The Iris Ceramica Group Historical Museum tells a story that begins in 1961. It is dedicated to everyone who has been a part of this story and helped to keep its ideas and values alive.

POLLUTION 2018 - RefleAction

For the 36th edition of Cersaie 2018 the Iris Ceramica Group presented the POLLUTION 2018 – RefleAction project, in partnership with the MC A studio and the SOS School of Sustainability in Piazza Santo Stefano in Bologna. The temporary installation retraced the path started in 1972 taking shape in the same place that hosted it then. Designed by the architects of SOS, 40 young oaks emerge from Bologna’s historic centre, in an artificial terrain created from a large reflective slab with a striking geometry that aims to subvert the usual relationship between the city and nature. Material therefore becomes nature, just like the Active Clean Air & Antibacterial Ceramic™ technology becomes the surfaces of the narrative pathway, mapping out the road of reflection on important environmental themes.

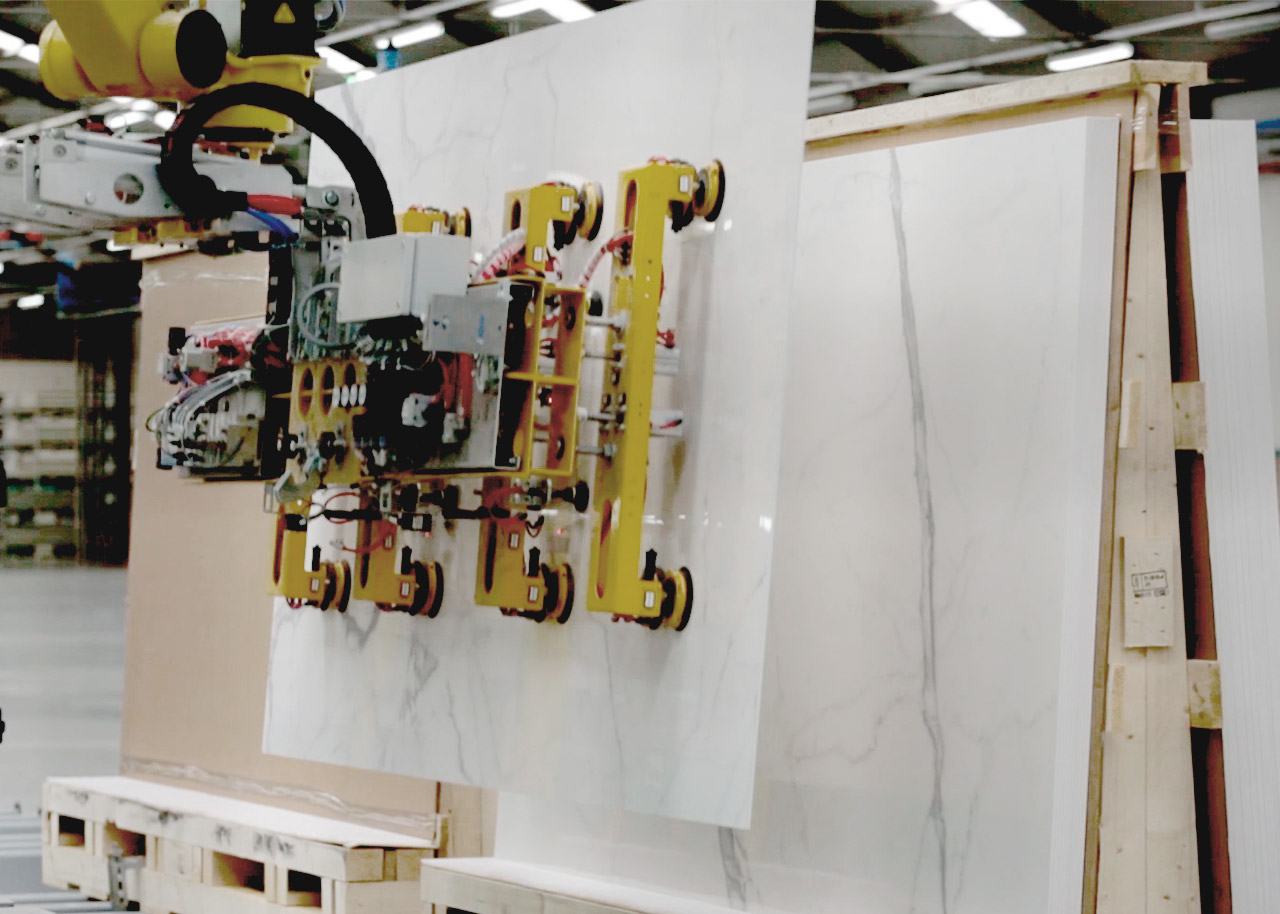

Stonepeak first US producer of maxi ceramic tiles

Stonepeak announces the launch of its first production line in the United States dedicated to large format tiles. The production plant, located in the hills of Tennessee, is the first American company to produce on site maxi 300x150 cm porcelain tiles that are only 6 mm thick. A strategic commercial choice that comes from the desire to be a global supplier in order to promptly meet the needs of a new market segment in constant growth, guaranteeing shorter delivery times and overall logistics efficiency.

Romano and Federica Minozzi acknowledged at the 21st "EY Enterpreneur of the year" awards

The Innovation Award was presented to Romano Minozzi and Federica Minozzi, Chairman and CEO of the Iris Ceramica Group, “for succeeding in exploring new ways of broadening the confines of ceramics in Italy and all over the world, creating products combining innovation in materials and colours with advanced technologies, study of new combinations of materials and an ability to rethink styles and functions, making sustainability a key to the company’s competitiveness”.

Oficina Tecnica opens in Madrid: a new gallery and showroom operated by Matimex

OFICINA TECNICA is the name of the new showroom opened by MATIMEX, an Iris Ceramica Group company concerned with distribution and sale of the Group’s brands in Spain, Portugal and parts of Latin America. The name reflects the nature of the place, a place to work together, where architects can find world-class workshops, events and initiatives. Not a conventional showroom, but a true hub of architecture for professionals and fans, offering a complete, highly qualified technical and commercial support service; a space open to the public where people can come to know and appreciate the Group’s porcelain brands, viewing the many different textures, sizes and finishes that make every single tile a true item of décor.

Developed by GranitiFiandre, a leader in the production of full-body technical porcelain sector for over 50 years, SapienStone is the result of an ambitious research project: to combine visual perfection, excellent performance, practicality and absolute hygiene in a single product. The quality of Fiandre porcelain slabs guarantees the exceptional characteristics of SapienStone featuring a long-lasting, unalterable product that is resistant to the most common forms of damage and wear: knocks, scratches and abrasions as well as a natural resistance to fire, heat, frost and thermal shock. These luxury porcelain slabs are also total non-porous, waterproof, and resistant to chemicals and stains, which make them easy to clean and minimizes maintenance. Huge advantage for a huge surface: SapienStone comes in maxi-slabs , with an ultra-light thickness. The slabs are easy to work with, in a wide range of furniture design applications, including kitchen countertops, tables, wall units and shelves, vanity tops, shower trays, baths and barbecue tops. The SapienStone color range is the result of a careful selection of the best raw materials and the research of the Fiandre expert technicians. These options allow designers to make the most of their design ideas. Exclusive, timeless shades precious grains, soft shading and elegant color contrasts can be combined with a choice of two finishes: polished and semi-polished. For a perfect blend of style solutions, these extraordinary furnishing surfaces can be united with matching GranitiFiandre floor and wall products.

Diesel Living with Iris Ceramica

Diesel Living with Iris Ceramica: a partnership that brings together the creativity and unmistakeable taste of the international lifestyle brand and the expertise and high-end technology that made the Modena-based ceramics manufacturer stand out from its early days. The product design is by Diesel Style Office, and the Iris Ceramica research and development department put its know-how and skills into developing and manufacturing the final product.

FAB Fiandre Architectural Bureau

FAB Architectural Bureau is the new multi-purpose exhibition format by Fiandre. An exhibition area for innovative ceramic products, FAB is also a platform for cultural dissemination, promoting initiatives where the central theme of architecture is tackled via a novel interdisciplinary approach. Located in Berlin, Milan and Castellarano, FAB exhibits an exclusive selection of porcelain stoneware for floorings, coatings, facades and furnishings. FAB works in both the professional field, offering advanced solutions for designers and companies, as well as the cultural arena, involving national and international authorities from the worlds of architecture, design, communication and art, contributing to the creation of a virtuous informative circle.

SuperSurfaceSpace

SuperSurfaceSpace is the exhibition gallery and showroom of Iris Ceramica, located in the center of Moscow. This gallery is dedicated to promoting the culture of architecture and design. This project consists in creating an exhibition area where people can see the latest collections of the Group's brands in an office environment, where visitors can discuss with the Group's representatives and technicians about possible application solutions.

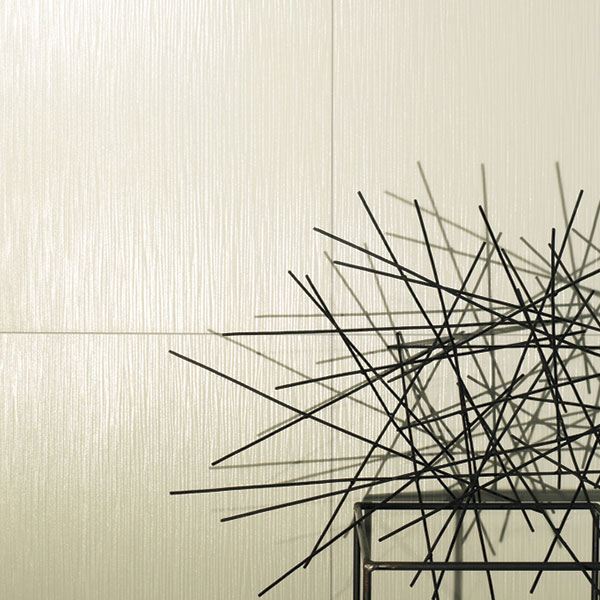

Collection: Hi lite (Iris)

Hi Lite proposes neutral and refined colors, textural surfaces with resin or concrete effects, metal glints, decorative textures and artistic graphics featuring lively colors. Inspirations and suggestions on large tiles to dress architecture and contemporary furnishing with new materials, that have incredible features: Wear resistant, Frost proof, Stain resistant, Weather proof, Fully customizable.

The Hi Lite collections are:

* Steelway

* Avenue XXL

* Metal XXL

* Artsy

Collection: MaxFine (FMG)

MaxFine very innovative collection that it breaks down the barriers between surfaces for architecture and even furnishings. Strong but not heavy at all, these tiles can be very large and incredibly thick to be settled as floors, wall coverings, also for custom-made furnishing and finishings. These are ceramic slabs that can be manufactured in 320x160 centimeters with an incredible lifespan and can be also personalized.

Collection: Maximum (Fiandre)

Maximum combines the classic features that have always distinguished Fiandre’s porcelain stoneware from all the other ones. Featuring new qualities, high performance, strength, flexibility and ductility. Maximum offers fine, decorative solutions, enriched by inimitable color variations and vein effects that are always unique. Glossy surfaces, elegant details, and fine veins all contribute to increasing the perceived value of any environment, respecting and enhancing the stylistic choices of the designer and the wishes of the client. Maximum enters the realm of products recommended for industrial design and custom-made furnishings. The resistance and ease of cleaning already appreciated in porcelain stoneware for floors and walls, are today on offer again with Maximum with a broader surface area, unbroken and free of discontinuities, and therefore recommended for kitchen counter tops, table and coffee table tops, seating and bathroom accessories. The size of Maximum is not the only remarkable feature that makes them comparable to the most exquisite and rare quarry marbles. This product is available also in large sizes (300x150 centimeters).

Collection: Ultra (Ariostea)

The flexibility of ULTRA technology allows the various product collections developed by Ariostea to be completely adapted to generate projects ranging from simple flooring or coverings for large or small surfaces to object-based applications and furnishing accessories. Using this new concept that combines light weight and technical performance, it is now possible to create genuine products or installations with the added benefits that come with ceramic technology. The very nature of the material also lets designers apply each of these possibilities in indoor and outdoor environments to develop smooth, curved and even backlit surfaces. Considering its 5.12 square meters for each slab (320x160 centimeters), it is the new reference point for designers and for all the work where size makes the difference.

* Ultra Marmi (Marble)

* Ultra Onici (Onyx)

* Ultra Iridium

* Ultra Metal

* Ultra ICementi (Concrete)

* Ultra Pietre (Stones)

* Ultra Teknostone

Collection: E-wood (Iris Ceramica)

Iris Ceramica's technological research has developed five varieties reproducing resistant and prestigious woods: White, Blonde, Oak, Grey and Black are the colors that show off the collection's warm natural hues to make the most of any space. The name E-wood stands for a new generation of tiles in many different styles from contemporary to vintage, from minimal to elegant. The surfaces of E-wood panels faithfully reproduce the look and the elaborate structure of wooden panels, with all the specific qualities of a natural material. This product is very successful when used for kitchen floor, bathroom floor and also for the balcony, due to its resistance and lifespan.

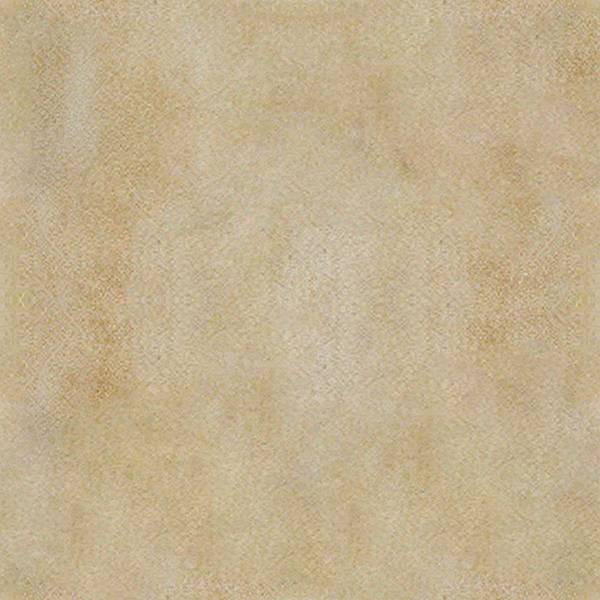

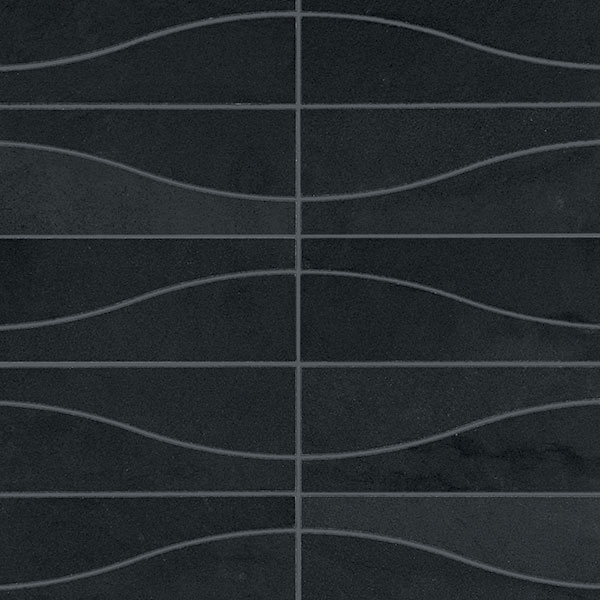

Collection: Just Tiles (Porcelaingres)

The Just collections have been developed in collaboration with a fabulous team of architects and interior designers who have requested something very specific: a simple ceramic tile but something that is still unknown. From that request, many ideas have been researched and finally became reality with the collections:

* Just Cementi (Concrete): The new collection Just Cementi, which draws its inspiration from elegant architecture and from the typical young look of modern lofts, evokes the authentic “City-Life-Style” of contemporary times.

*Just Grey: This is the new porcelain stoneware collection tailored to the needs of sophisticated architecture. Grey is never just plain grey: eight different shades span the spectrum between deep black and pure white.

* Just Beige : The new porcelain stoneware range offers a variety of beige tones. The eight coordinated tones and three surface structures give a subtly exclusive feeling to any room.

Maxi lastre

At the beginning of the decade the turning point in the technical-productive field is big, even maxi. The companies of the group are at most the first two times in the porcelain stoneware market (300x150cm). A turning point, the dimensional one, which will revolutionize the areas of use and application of this product.

Collection: Pietra d'Origine (Eiffelgres)

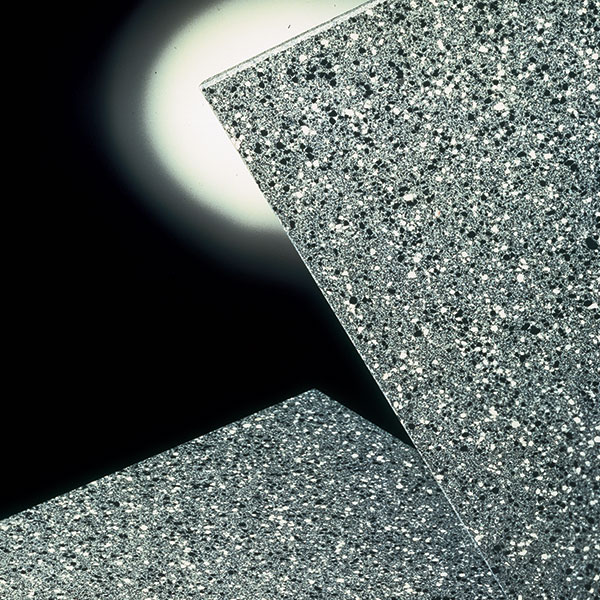

Pietra d’Origine by Eiffelgres is all about the minimal in visual terms, is the dot: the origin of all other shapes and symbols. Here, the dot is interpreted through little inclusions. We might say that Pietra d’Origine could be classified as a fine-grained sedimentary rock which contains no fossils but does contain inclusions no more than two millimeters in size which determine its surface appearance. It’s a stone which is not stratified and unlikely to exfoliate. Tiles from the Pietra d’Origine collection are available in the 90x60, 90x30,60x60, 60x30 and 30x30 cm sizes as well as in strips measuring 15x60, 10x60 or 5x60 and ornamental pieces fixed on mesh, such as Mosaico, Mattoncino, Quadrotta Sfalsata and Foglia. The whole range is produced 11 mm thick, solid, single-gauge, squared and ground.

A NEW STRATEGY In 2011, the 50th anniversary of the foundation of Iris Ceramica, the delisting of GranitiFriandre brings great news: a new organization chart aimed at stimulating the synergies in to compete among the various companies within the group. A different scenario where the group could facilitate the projection of each brand, yet helping the entire group to have more visibility and this allowed the brands to perform individually.

-10

Extreme Press

The Extreme press, inaugurated at the Castellarano plant, is able to produce giant porcelain tiles: 150x75 centimeters.

GranitiFiandre was a partner of the Italian General

Committee for Expo 2010.

The Pavilion Italy at Expo of Shanghai (China) displayed flooring and wall coatings such as the porcelain stoneware slab XL 120 Anthracite Ground manufactured by GranitiFiandre.

Active Clean Air & Antibacterial Ceramic™

Fiandre, Iris Ceramica and FMG Fabbrica Marmi e Graniti, have improved a new production method in their research and innovation activity, geared to materials with an active ingredient that helps to improve the environmental quality. This production method makes possible the production of ceramic materials for floors and walls, and they are able to make a concrete antibacterial action and they lead to a reduction of pollutants, which unfortunately are a constant in the current urban condition. The collection ACTIVE Clean Air & Antibacterial Ceramic TM can be laid, both in the indoor and outdoor environments of buildings, materials that actively and permanently contribute to a better environment. 1) Bactericidal Effect : The strong oxidizing power of the ACTIVE Clean Air & Antibacterial Ceramic™ photocatalytic action is able to remove the bacteria, some of which are very dangerous for the humans. Photocatalysis does not really kill the bacteria but it decomposes them, irretrievably damaging their cells and causing their death. ACTIVE Clean Air & Antibacterial Ceramic™ removes 100% of these bacterial strains. 2) Self-cleaning Properties : The photocatalytic activity of the TiO2 of the ACTIVE Clean Air & Antibacterial Ceramic™ tiles exerts a dual effect on the daily dirt on the floors and walls (powder, organic residues, etc.) So, the dirt removal is easier and the use of detergents is reduced. 3) Anti-odor Efficiency : Another characteristic is that ACTIVE Clean Air & Antibacterial Ceramic™ is able to degrade the most common organic molecules that cause the smell. 4) Effectiveness against NOx : The photocatalytic process due to the TiO2 deposited on the ACTIVE Clean Air & Antibacterial Ceramic™ tiles destroys and transforms a lot of pollutants and toxic substances in harmless compounds such as nitrates, sulfates and carbonates.

MA.DE and Compasso d'oro (Gold Compass) The collections of Iris Ceramica MA.DE and BRILLIANT compete for the XXI edition of the Compasso d'oro.

SpazioFMG & New Techniques

Iris Ceramica and FMG Fabbrica Marmi e Graniti’s gallery and showroom lauched a new, bigger, more complex layout with completely new design and interiors. Opened in 2007 at Via Bergognone 27 in Milan, SpazioFMG is the place where architecture meets the city, where professionals from all over the world meet to talk about current issues in the discipline and in society. Ever since it was first conceived, on the basis of the convictions and philosophy of the Iris Ceramica and FMG Fabbrica Marmi e Graniti brands, SpazioFMG per l’architettura has declared its mission of promoting awareness of issues related to environmental sustainability in the trade and among the public, with the aim of making complex concepts, methods and synergies a common heritage. With this background, the gallery also became the home of the Floornature.com architecture portal, allowing ideas and suggestions received locally to be merged with those received over the internet and through the new media. The gallery’s new exhibition layout underlines this point of arrival and the opening of new exhibition projects in collaboration with Floornature.com.

Collection: Legni High Tech (Wood) (Ariostea)

High tech woods faithfully reproduce the look, tactile feeling, and veins of natural wood. A product so close to perfection, manufactured without touching a leaf. Its large listels are unique, this is the best way to appreciate the uniqueness of these products. You can feel the warmth and structure of wood; Ariostea has combined these natural qualities, in a ceramic wood tile, with technical characteristics that make these products more resistant to deep abrasion, water, heat, chemical agents. They do not require any treatment before or after installation or in the following years. They offer the visual impact of wood porcelain tiles with the strength of stone: compact tiles of ultra-fine solid porcelain stoneware reconciling the strip design of top quality natural parquet with the need for strength in today's interiors. Ariostea presented vintage oak slabs in the large size of 150 centimeters.

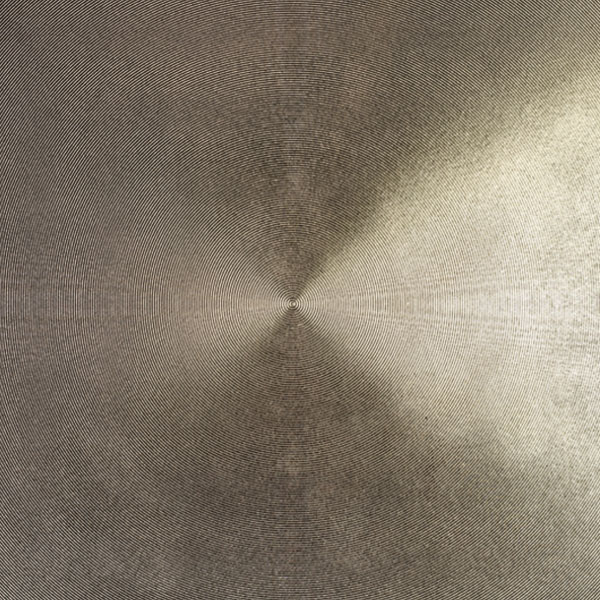

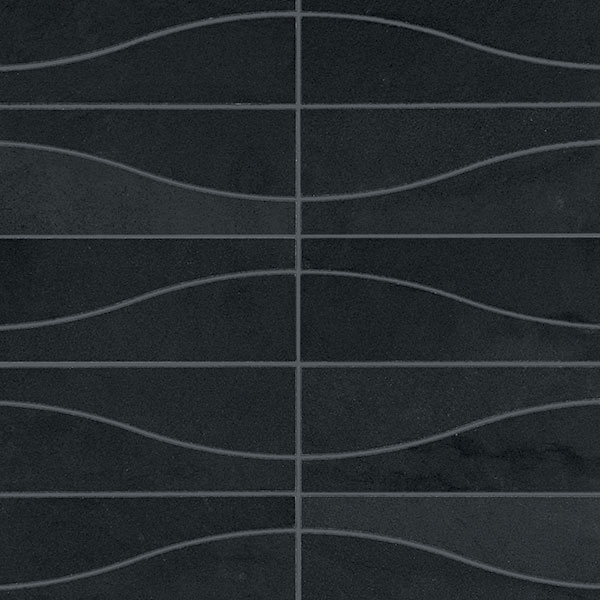

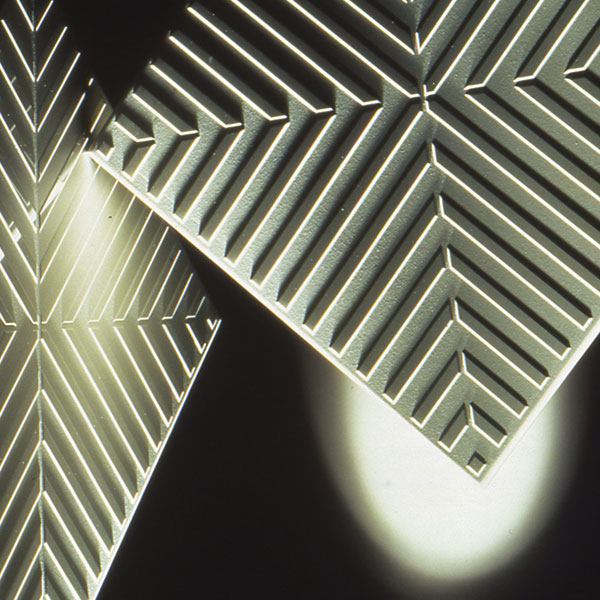

Collection: Luminar (GranitiFiandre)

The Luminar collection brought together different fields of knowledge, the "warp" of technology and the "woof" of a cultural background that draws on several sectors to craft the excellence of GranitiFiandre. Moreover, Luminar went beyond the classic effects of light found in nature because it offered an innovative solution where matter lets itself be shaped by light, creating a beautiful shimmer no matter what the conditions are: in full light, in shadow, and even in moonlight. The surface of the material is covered by a continuous series of concentric circular engravings: the result is a bright, reflective surface, created in part through a special treatment that is applied to the technical porcelain stoneware to ensure outstanding aesthetic results.

Collection: MA.DE (Iris Ceramica)

Ceramic preciousness with a new name: MA.DE. New colors, new surfaces and a new size: the 120x60 centimeters, to once again enhance the textures and attractiveness of the collection. The “MA.DE” collection has received the most important international awards: the first ceramic tile in ADI Design Index 2006, the Guide for the Industrial Design Association.

Collection: GeoDiamond (Fiandre)

After the the acquisition of Hydrodesign, GranitiFiandre began to experiment with materials: cut and adjusted according to new shapes and geometric forms rich in ideas to create new concepts of interior design. In the GeoDiamond collection, the metal blends for the first time with the coloured-in body porcelain stoneware.

Collection: Pietra d'Aragona e Pietra di Brera (Eiffelgres)

The evolution towards perfection is unstoppable and in 2006 Eiffelgres surprised everyone with the collections Pietra d’Aragona meaning Aragon Stone and Pietra di Brera meaning Brera Stone. The Pietra d’Aragona collection, was inspired by the most delicate limestone, a product of an innovative hi-tech productive process perfected in Eiffelgres’s research laboratories which makes it possible to obtain the randomness that was in the past the exclusive prerogative of natural quarried stones. Every slab in the Pietra d’Aragona collection is unique and unrepeatable, perfect for surrounding you with a feeling of softness to create an elegant, refined setting. In Pietra d’Aragona, Eiffelgres combines the aesthetics and naturalness of quarried stone with the high performance of hi-tech porcelain stoneware. Also, the Pietra di Brera collection was a product of Eiffelgres researchers’ ongoing interaction with the engineers and architects who are redesigning the world’s cities and building large-scale public spaces and housing developments.

After the investment in Germany, it was time for the biggest step ever: The acquisition of a company called Crossville in Tennessee - United States. A big dream of Romano Minozzi, who planned, along with the creation of the

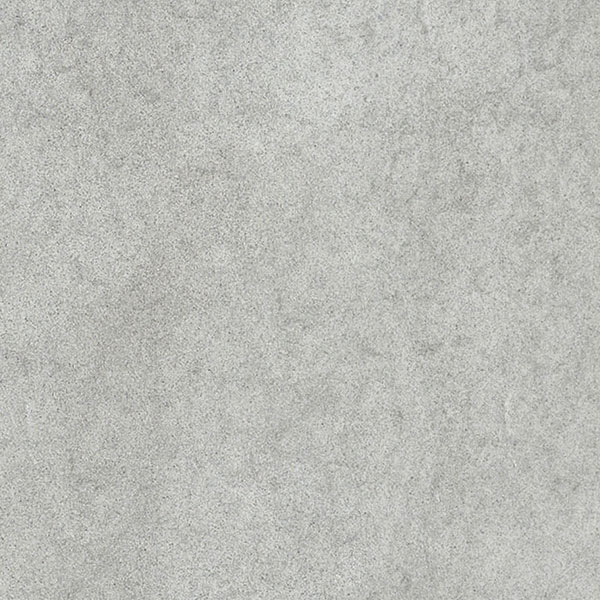

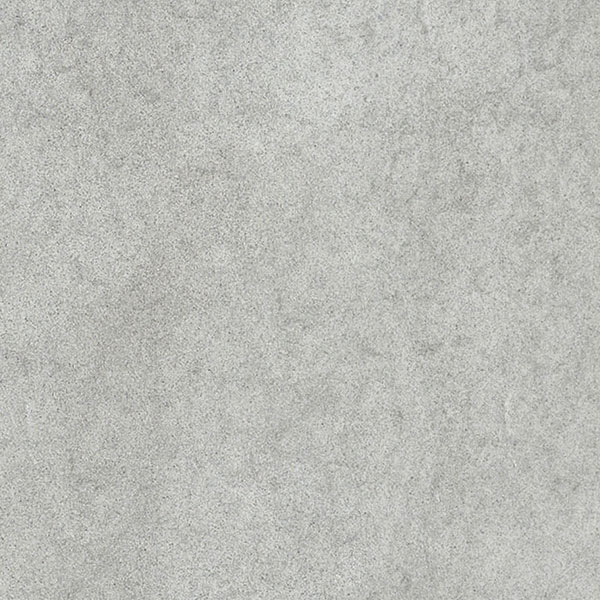

Collection: Limestone (Stonepeak Ceramics)

Subtle organic beauty marks StonePeak's unglazed porcelain limestone. This line features the thru-body color variations and dimensionality of real limestone, while delivering precisely squared corners and greater durability than natural stone. And like real limestone, no two StonePeak Limestone tiles are alike. This series comes with a full range of complementary trims and is ideally matched for commercial and residential settings such as hotels, hospitals, airports, shopping malls, libraries, and in residential flooring, walls, patios, walkways and more.

Porcelaingres was founded in 2003 and since then, the company has been producing slabs in absolutely high quality porcelain stoneware, in one of the most modern manufacturing facilities in Europe. The company has its headquarters in Vetschau (Germany), and also a cutting edge production plant guided by the principles of sustainability with an indoor area of 70.000 square meters. Porcelaingres is an affiliate of GranitiFiandre SpA, and has a production capacity of 6 million square meters per year.

The conditions of extreme competitiveness in the market require companies to focus on their businesses. As a direct consequence, there is a necessity of having professional security solutions capable of delivering an outstanding assistance that satisfies many different types of clients. In

Collection: Pietre High Tech (Ariostea)

In 2002, Ariostea launched Pietre High Tech meaning High Tech Stone, this collection combines the warmth of stone floors, the strength of patented technology. These are High tech floor and wall coverings perfect for both indoor and outdoor solutions thanks to the various surface finishes available. The manufactured stone is made up exclusively of natural raw materials and minerals that are transformed using a production process similar to the natural rock forming process, giving life to an extremely compact product, homogeneous throughout its body. It’s defined as a veined coloured-in body porcelain stoneware manufactured in two sizes: 60x30 centimeters e 60x60 centimeters.

Collection: Sandstein (Porcelaingres)

The Sandstein collection represents all the natural features of quarry stones, thanks to the raw materials used in all thicknesses that guarantee the most authentic design. This collection, which draws its esthetic inspiration from the most varied rock beddings, reveals the innovative design solutions of Porcelaingres in all their splendor. The curious color and material combinations, reflecting natural sedimentary layers, bring harmony to the decor.

Thick veined porcelain stoneware slabs (60x60 centimeters)

At that time, Ariostea was already the market leader in thick veined porcelain tile. The vaining on this type of porcelain tile is also reproduced in tile body. This technique guarantees that the product aesthetics won’t be compromised in any situation.

Hydrodesign was purchased by Iris Group in 2001 and resold in 2009. During this time, the company continued its research in the application of working techniques of natural stones, and invested a great amount of resources in the project ”fuga zero”; a production process that allows us to obtain decorative elements in one single piece by using traditional cutting and or water jet method.

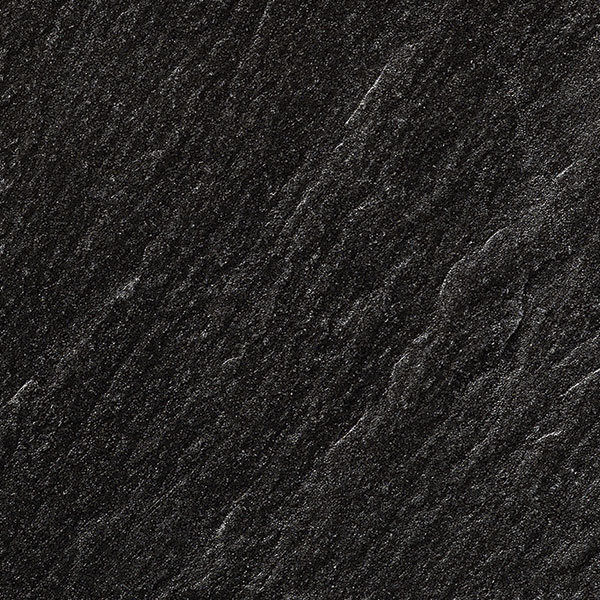

Collection: Argent and Lastranera (Eiffelgres)

The Argent and Lastranera collections belong to Eiffelgres. The collection Argent an Eiffelgres stone of unique color particularly well-suited to today’s architectural designs. It is produced using latest generation technologies, the most advanced in the world, to restore all the expressive richness of natural stone. It is pure matter created with selected earths and minerals, skilfully dosed and mixed. The Collection Lastranera perfectly reproduces natural slate, choosing technology to recreate nature.

Collection: High Tech Marble (Ariostea)

Thanks to patented technologies, Ariostea is able to reproduce in a few hours in the factory what nature takes thousand of years to create. High tech marble floor and wall coverings, classic yet innovative and extremely resistant. In this way Ariostea helps to keep alive the memory of marbles which are exhausted in nature by reproducing them and creating contemporary products.

Floornature.com was created by Romano Minozzi in 2001 to be a portal for information and documentation on how fast changes are happening in the international architectural and design markets. The website Floornature.com is pretty straightforward and clean, but yet complete and innovative. It has become a valuable choice and relevant media, as a web magazine specially for interior designers, professionals and companies.

The Granitech division was established in 2000 to meet the new market demand for turn-key systems and for the provision of customized services.

The 1990s

The "nineties" were years for many specialized companies to be created from scratch. Many countries, institutions, companies, and organizations were prosperous during that time. Some small companies were acquired to preserve individual segments of the market, even niche market. It was a fast-faced period of development in physical and geographical extension. In less than a decade, the internet would have become a game changer to the wider society and would also have changed the communication between business to business and business to clients having mailing lists, emails, online forums and bulletin boards, personal websites and the first blogs.

Collection: Stardust, Premiere and I Veneziani (Ariostea)

In 1999, the collections Stardust", "Premiere" and "I Veneziani were launched. The three collections were very important thanks to the fact that they marked the beginning of the mass-produced porcelain stoneware.

Collection: Irisgres (Iris Ceramica)

In 1999, Iris Ceramica launches Irisgres a glazed porcelain stoneware with minimum water absorption: only 0.04%. These floors were also used for swimming pools due to a truly revolutionary quality and product lifespan.

FMG Fabbrica Marmi e Graniti , was founded in 1998. The manufacturing process of its products involve technical perfection combined with beauty, and the quality of materials enhanced by technology. The aim is to reach creative architects, interior designers and design lovers through a wide range of effects. Nowadays, FMG offers even a wider range of effects such as Marble, Stone, Granite, Wood, Concrete, Design and Iron. These products are created to be used in many different situations, either for small living spaces or large projects.

Technomix was founded in 1998, in Fiorano Modenese (Fiorano Modenese is a comune in the province of Modena in the Italian region Emilia-Romagna, located about 45 kilometres west of Bologna). It’s a very modern plant that produce annually 1.5 million tonnes of mixed materials

Technoriunite was a result of a merger when “Technoposa” and “Ceramiche Riunite SRL”. These two companies were members of the Iris Group, yet both specialized in laying techniques. The aim of the merger is to combine techniques, share knowledge coming from extensive researches, strengthen and improve customer services.

Manufactured Marbles and Travertines

The first marbles and travertines were created in 1998. It was considered a massive that once again leaves was considered a game changer.

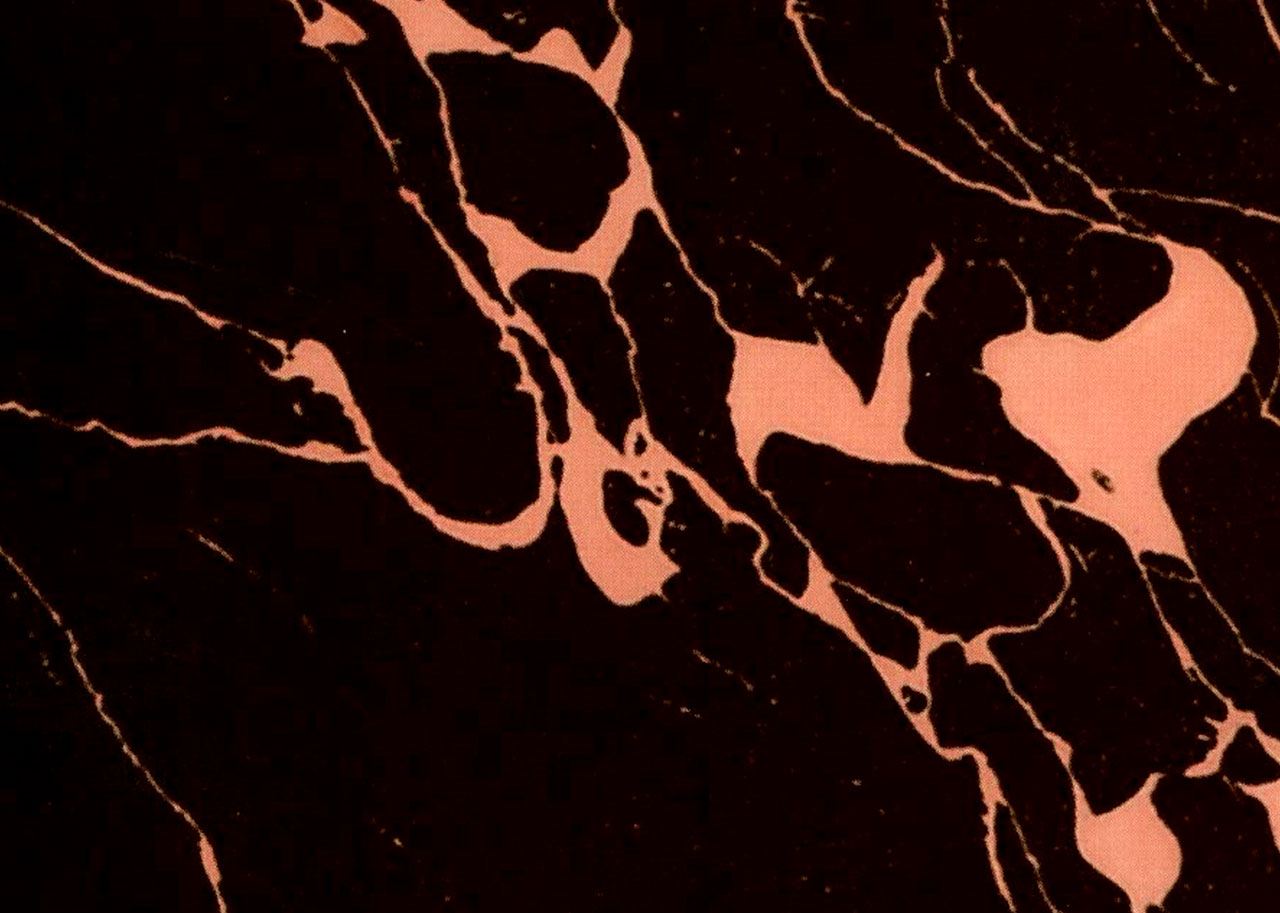

Collection: Marble and Granite (FMG)

The first Marble and Granite collections were created in 1998, a success at the time. They were called Giada (Jade), Absolute, Le Gemme (Gems), Tavelle, Marmi (Marble), Ardesia (Slate), Pietre Naturali e Rocks (Natural Stones and Rocks), Centenari (Centenary), Granit (Granite) and Unicolor.

Collezione Etrusca (Ariostea)

The Etrusca collection, meaning Etruscan from Ariostea was created with a concept of a tribute to the past, to the traditions connected to the ceramic tiles. From this collection, the tile Volterra expressed all the feelings and emotions connected to the past. Even in the classic size of 30x30 centimeters, this tile was object of desire from many people around the world. The tile lovers embraced the retro style and the product was very successful.

Collection: GeoNatura (Ariostea)

The GeoNatura collection was launched at the end of 1997 by Ariostea in two sizes: 40x40 centimeters and 30x30 centimeters. It was classified as a natural finish porcelain tile collection. The unique and remarkable reference to different continents allowed the product to be appreciated worldwide. The best selling product from this collection was the product “India”.

Savoy Canada was once a subsidiary of GranitiFiandre, which was responsible for distributing and storing material to the Canadian market. The brand had a significant market share in Toronto, Montreal and Vancouver particularly in the non-residential sector while managed by GranitiFiandre. In 2017 it was sold to Canadian Shnier, Gesco LP.

Technokolla was founded in 1995, it has climbed the success ladder in a short time landing in a landing position thanks to the constant research for new solutions for the world of construction: bonding agents for the building trade, adhesives for fixing wall and floor cladding materials, waterproofing coatings, grouting, sealants and products for preparing substrates. In July 2011 it was sold to the Sika Swiss multinational.

Collection: Ambre (GranitiFiandre)

By the mid-1990s the Ambre collection added new chromatic effects that are still admired these days. It was a great period in which Ariostea also launched Belforte , a high quality collection that could demonstrate resistance and excellent quality once they were laid.

Collection: Rockwell White (GranitiFiandre)

The Rockwel White collection from GranitiFiandre marks the decisive moment of tiles getting a new dimension of 60x60 centimeters. Therefore, Rockwell White is a type of porcelain stoneware for indoors and outdoors, which became part of the Granite series. Until these days, Granite is still a universal symbol of hardness, compactness and durability.

Ariostea was acquired by Iris Group in 1993, from that on it has always been a company with high technological products, thanks to the particular attention to the impact on the environment. Moreover, its high quality products come from the with most refined and valuable raw materials. As a consequence of this technological quest, many machines were created being directly connected to the need to produce ever-increasing amounts of full-scale technical porcelain, with high quality levels. This also led to the creation of new production lines, much different from those once designed for the Iris group’s main plants.

The Room of the Guardians: "a restoration with the highest standards" The deep bond between the Italian Ceramic Culture and the provinces of Reggio Emilia and Modena inspired Iris Group to support the restoration of the “Palazzo Ducale di Sassuolo”, meaning Ducal Palace of Sassuolo which is a Baroque villa located in the town of Sassuolo, near Modena, northern Italy. The restoration was a project from the city authorities but Romano Minozzi got inspired by the project and also embraced the idea of collaborating for the restoration of the “Salone delle Guardie”, meaning The Room of the Guardians. The Palace's restoration, started in 1987 and was completed in 1998, marking 11 years of intensive and detailed work, amazing decorated rooms on the noble floor, incredible paintings and decorations. In 2011, twenty years after the end of the restoration, the room was chosen for the official announcement for the celebrations of the 50th anniversary of Iris Ceramica, founded in 1961.

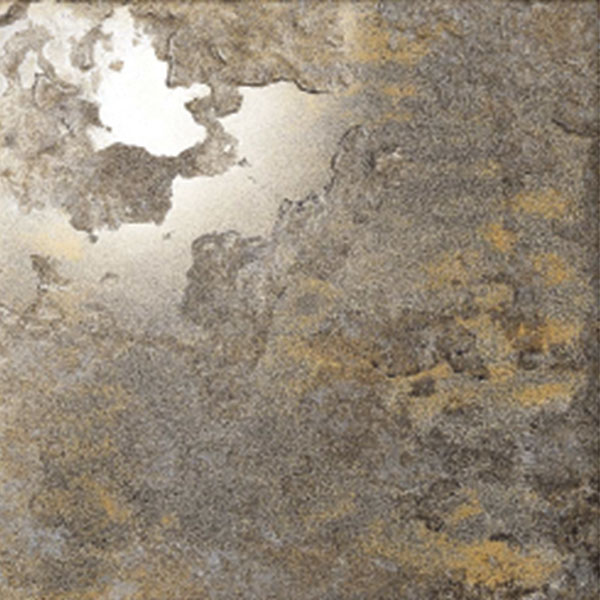

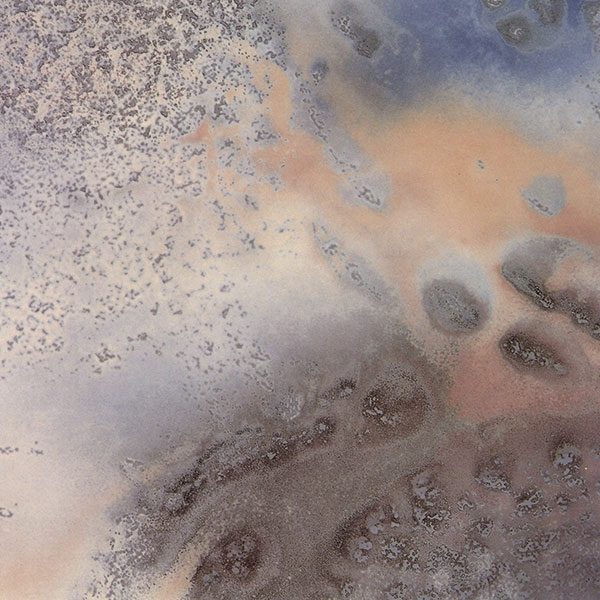

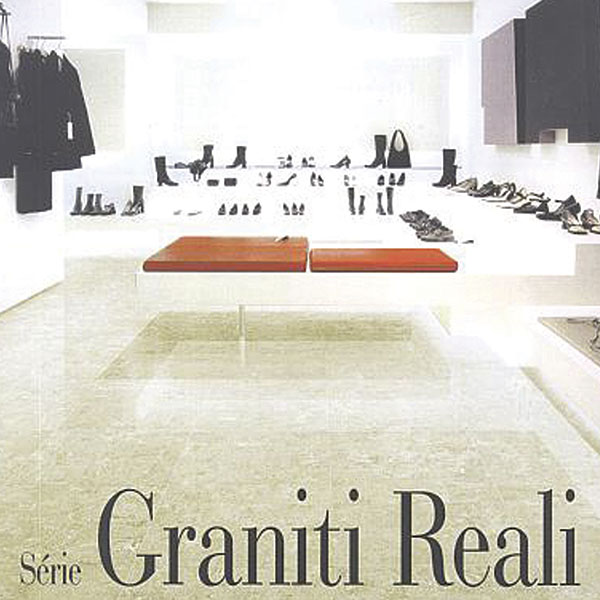

Collection: Graniti Reali (GranitiFiandre)

This collection is called Graniti Reali , meaning "Royal Granites" High performance porcelain tile for heavy-duty applications. Materials that Fiandre creates in collaboration with important companies that make research and excellence their primary goal, along with creating new possibilities. The products were a result of a meticulous research into the morphology of minerals and the chromaticities of natural granites combined with a new technology capable of replicating the nuances of a particular granite after solidification.

Collection: Alabastro (Ariostea)

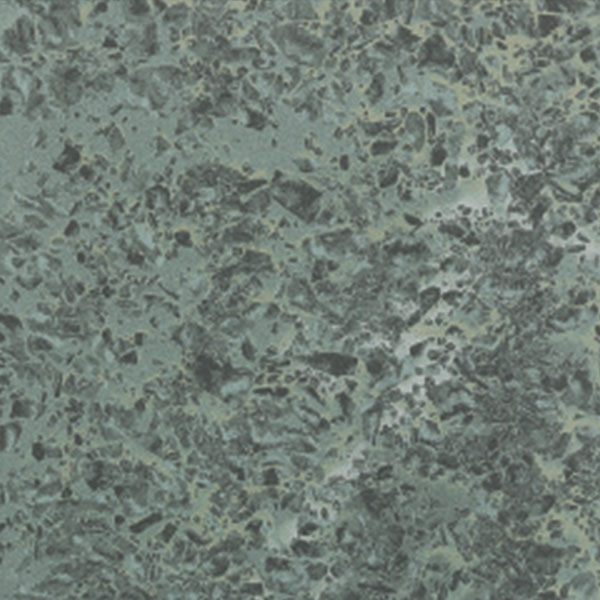

The Alabastro collection, meaning Alabaster was launched in 1994, and it was available in two sizes, the 30x30centimeters and the 40x40centimeters. These measurements were considered quite large in that period. It was basically a new porcelain stoneware line with two types of surface: Polished and Satin, also found in different shades of color. It’s important to mention that, from this collection the color “Alabastro Green” became a huge market success.

Matimex was acquired by Iris Group, and from that on the company gained market share and new customers from the its biggest competitors abroad, the tiles from Spain. A huge achievement for that period, owing to the fact that Matimex was able to strengthen the participation of Iris Group abroad in countries such as Spain, Portugal and Mexico.

The first Geologica Shop was inaugurated in Milan and it was the beginning of a new entrepreneurial experience. Nowadays, the brand Geologica Shop, either in direct management or as a franchise, is estimated to have approximately 100 (a hundred) shops around the world. The first Geologica Shop opened abroad was in Chicago, yet this marks a the beginning of a very successful journey in this type of business.

Semigres, wall coverings

Iris Group has always been very successful with floors. Its creations were the outcome of constant research and development conducted in-house, a heritage of unique know-how that provides the basis for yet more unique materials. The next step for the company was the to create the right solution for wall coverings, so semigres was created. The first impressions in different markets around the world were great and the feedback was positive.

Collection: Pietre prezione (GranitiFiandre)

The collection Pietre Preziose meaning Precious Stones focused on sophisticated interpretations of rare and precious stones and granites. Its products marked a new era for the porcelain tiles.

Collection: MARMI e JURA (Ariostea)

The Marmi collection paves the way for a whole "thread" with references to types of marbles while the Jura collection brings a new wave of fascinating colors. The shades of green were the most requested and in many homes so this "change" of coatings and floors became something essential and unavoidable.

The 1980s

The development of the Italian ceramic companies finally started to go to the right direction by the end of the 1970s. The effects of that improvement could be seen in the early 1980s, when the production for the first time exceeded 300 million square meters. This was very impressive result for the provinces of Reggio Emilia and Modena, where the exportation represented approximately 50% of the whole production. However, this is a short-lived euphoria since the 1980s also brought again strong winds of crisis. In fact, it was an economic downturn that struck the industrial building construction industry in Italy, so as a result the ceramic sector was in great danger. Some ceramic companies had to really learn how to navigate the winds of crisis, but unfortunately all the sales orders from abroad weren’t enough to guarantee the survival of many companies. Once again, we were caught in a challenging situation for the ceramic industry in Reggio Emilia and Modena. The ceramic sector needed fresh ideas to overcome the challenges, so Iris Group leaded by Romano Minozzi decided to keep the investments on technological innovations. The first steps were to invest in electronic and automated production lines, so manufacturing costs would be much lower and the company could finally face the crises. It’s also known within the Iris Group that the turning point for this situation was the fact the Monocottura (Single-firing) technique that allowed the company to overcome this situation due to its innovative approach.

The company GranitiFiandre S.p.A was founded in 1989. It was a result of a merger between Ceramica Castellarano and Ceramiche Le Fiandre S.p.A. Before the plant was built, the place was a small farm called Fiandre, so that’s the reason Fiandre became part of its brand name.

The 1980s and early 1990s were times of successful magazines either for entertainment or style, so the idea of creating a professional magazine that could connect the commercial-industrial building constructors and professionals such as architects, interior designers and engineers was something considered more than necessary. The magazine was expected to be elegant and fashionable but also featured with a lot of technical details for the companies. This is how it was from the first issue, MATERIA became a very important tool for all appreciators of tiles, either professionals or companies to be informed about everything in ceramic world.

Ceramic Floor Tile with 9mm Thickness

At that time, 40x40 centimeters were considered large size tiles. However in 1989, the thickness was considered an amazing achievement due to its practicality.

Another decisive moment for Iris Group happened in 1987, with the help of Romani Minozzi, Iris Ceramica took over Castellarano Fiandre.

Collection: Cottage (Ariostea)

Cottage is a very unique collection that recreates the unforgettable vintage tiles from Italy. The design and color recalled the Fiesole Tiles made from a red paste. It was produced using a single-fired technique and size chosen was 24x24 centimeters.

Collection: Floras Corindo (CCC)

The Floras Corindo collection expressed the evolution of Granite Tiles where “the granular” texture was larger and more visible . The Floras Corindo Granite tiles were considered attractive, durable and versatile, and were manufactured in many colors.

Collection: Designer Line (CCC)

The Designer Line collection was created by Biondi-Gasparini-Silvi's studio from Reggio Emilia. It’s a collection that offers opaque and glossy monochrome contrasts and these effects were obtained by polishing the reliefs on the surface.

Collection: Sabbia (Iris Ceramica)

With the Sabbia collection ( meaning sand collection), the level of elegance and the amazing quality of finishing regarding ceramic tiles became a great source of inspiration. As a consequence, the company decided to invest in different tile sizes, starting with a rectangular shape 30x20 centimeters.

The first Porcelain Stoneware

The incredible 1980s were years of transformation, but also tension towards the future. These were also years of innovation for the ceramic market, more specifically for the provinces of Reggio Emilia and Modena. As a consequence, the first porcelain stonewares were created as a futuristic design expression.

The single-fired stoneware tile collection had a great quality and it wasn’t just a simple building material but in fact it’s a product that caught the attention of many architects, interior designers and engineers. It landed almost at the same time in Italy and United States, becoming a reality in the American homes. In fact, the market acceptance of ceramic tiles became a reality and it’s considered impressive, due to the old American culture of wood, marbles and carpets.

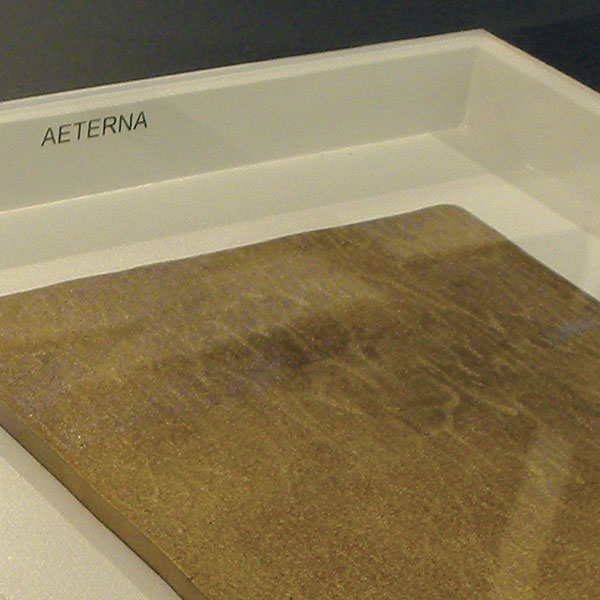

Collection: Aeterna Stain Resistant (Iris Ceramica)

At that time, the market expected to have a resistant tile against "strong dirty agents": oil, sludge, ink, wine and other liquids. The collection Aeterna would be the answer for these needs. It was very innovative tile to and easy to clean because it’s surface is impervious to liquid penetration and therefore stain resistant.

Green and eco-friendly businesses

The seventies were considered to be the years of development for the companies of Romano Minozzi. However, this is not the case for everyone else. It is in fact a complicated decade for ceramic companies in the province of Reggio Emilia and Modena, the huge amount of orders were seemed to disappear.

Only the successful and profitable companies continued to produce, for all the other companies there was the fate of a very difficult period called “Incorporation and Mergers”. As a result of this situation, in 1974, 10% of the production of the ceramic area had remained in the “Sassuolese” meaning city of Sassuolo. Also, in 1975 the export declined sharply (-30%).

The sector needed new ideas, as fast as possible. Consequently, the foreign market seemed an alternative since the seventies had been years of consolidation, but had also been years of great cultural breakthroughs and developments within business culture.

Nowadays, all the companies in the cities around the province of Modena such as Sassuolo, Fiorano, Maranello, Formigine, Castelvetro and also around the province of Reggio Emilia such as Scandiano, Casalgrande, Castellarano and Rubiera, share a common aim which is to be sustainable and environmental friendly by "becoming green" and raising the awareness about the environmental degradation that the early years of the ' 'Intensive' ceramic industrialization have caused.

This process happened by pursuing knowledge and practices that could lead to more environmentally friendly and ecologically responsible decisions and lifestyles, which can help to protect the environment and sustain its natural resources for current and future generations. Moreover, all the companies around these provinces are always focusing on creating new ideas that focus on these principles.

Collection: Aeterna (Iris)

Aeterna collection was the starting point in the culture of guaranteed long lasting floor. In that period, Aeterna was a very special tile and promised safety in any type of surface, even in situations where other materials had shown signs of scratch, abrasion and cracks.

Innovation: Monocottura (single-fired tiles) at 1200°C

The Edilcarani plant was, in that period, the most modern ceramic production plant of Iris Ceramica Group. It was also the most modern manufacturing plant the world, thanks to the Monocottura 1200 tile using noble clay. Monocottura is a popular Italian term given to single-fired tiles, the technique consists of single firing both glaze and body at the same time at 1200 °C.

In 1976 Iris Ceramica has launched many innovations onto the market and two of them were essential to the company. The first one was the new logo with the word Iris, in which the flower Iris became part of the logo and it was meticulously placed in the second letter "i" of the word. This logo is the same as we are used to seeing today and remains one of the most famous and recognizable brands of the entire ceramic industry worldwide. The second innovation is the launch of the Iris plant where white ceramic pastes are produced.

Collection: Tipì (Iris)

The incredible "Tipi" collection was launched onto the market in 1976. The product was created to be a wave of movement,when compared to the plain colors of the previous colors and finally geometric patterns with relief shapes started to decorate the tiles surfaces in different shades of color. At the time, the so called “Relief Tiles” were considered to be a breakthrough and were produced in 15x15 size.

Iris White Ceramic Paste

In 1976, IRIS Group launched its new factory called Iris where white ceramic pastes are produced.

Arco Smalti (meaning Arco Glazes) was founded in 1975. The Arco plant initially produced glazes for the ceramic industry. It was a great idea to invest and also to position this company in the market since Romano Minozzi had envisioned a different concept of production chain which combined with unique products has allowed the company to be extremely successful and competitive for several years.

GOLD MEDAL FROM THE PRESIDENT

In 1975, the Iris Research Laboratory receives a gold medal from the President of the Republic in Faenza. (an Italian city in the province of Ravenna, Emilia-Romagna). In this period, the laboratory had experimented and researched towards the rediscovery of the greatest ceramic traditions. As a result, Iris Ceramica tiles were the first tiles to be exposed at the MIC, the International Museum of Ceramics in Faenza, and this collection is still considered to be the world's most assorted one.

Ecology equals Economy

In the early 1970s, Romano Minozzi decided to his personal crusade towards sustainability, so the concept Ecology equals Economy has been important to the company and still remains the most significant value. So as a consequence, these new “green” ideas were also written inside of the warehouses and production lines reminding everyone that the respect for the environment is essential and indispensable. The ecological turning point started by Romano Minozzi caught the attention of the most important national newspapers such as “La Repubblica”.

The Flooring Installers and the Ceramic Products The customer is always at the center of our attention, so it’s always necessary to be a “step forward”, and to achieve that , the company must understand the needs involved and to have an accurate focus on its objectives. Based on that, the company decided to invest in communication channels, but that was a time that internet was still a distant reality. From this need, Iris decided to create a brochure consisting of sixty pages with many photos and graphics, in which people could find all the information and understand the problems regarding ceramic materials and their uses. It was a powerful tool and also the most complete brochure for the creative work in the ceramic industry. Nowadays, the company’s main communication channel is its website.

Local Product & Product Miles

It’s no coincidence that Italian ceramic production has been constantly concentrated around a small area in the province of Modena and Reggio Emilia. It’s an outstanding accomplishment to be in possession of an incredible knowledge about the combinations of raw materials such as clay, sand and minerals. In fact, the magic of transforming materials through processes like batching, mixing and grinding, spray-drying, forming, drying, glazing, and firing is just fascinating, and many of these steps are now helped by Automation Control. In the past, it was already known that in order to produce incredibly resistant ceramic products, it was essential to use high-quality clay that luckily Romano Minozzi has always found within a few miles from the company in a place called Appennino Reggiano Modenese, meaning Reggio-Modena Appennines. Nowadays, it’s very common to hear about Local Product or Product Miles and how important it is to help the local businesses, and as a consequence, the local economy. However, back in the 1960s the concept of Local Product was a thousand miles away of our reality, but in our region this was already a reality to be proud of.

Collection: Exprimo (CCC)

Exprimo was the base of all new trends: it has been at the top of the sales charts for several years. A huge success not only within of the company but also in comparison with products from competitors.

Collection: Serena (CCC)

The collection Serena was inspired by Pietra Serena who still works for GranitiFiandre collections. Serene stone is a grayish sandstone particularly used in architecture and sculpture. In 1975, the Serena tiles were very small (15x15 centimeters). Nowadays, this stone is manufactured as large porcelain stoneware slab but the product attractiveness is still the same.

The Iris Ceramica Group became the world's leading group in the ceramic tile industry.

1973-1975 The first issue of the HUMUS magazine of Ceramics, Strategies and Techniques was published and distributed by the Iris Foundation and edited by he Al.SA agency (from Sergio Albergoni and Gianni Sassi). It was a unique and innovative editorial project published every four months. HUMUS magazine was considered to be very different from the traditional concepts "proposing a real critical instrument of innovation and implementation of new design concepts."

Pollution

In 1972, Iris Ceramica was the main sponsor for the "Pollution" artistic event to raise the awareness about pollution and its own distinctive causes and consequences. The event created by Gianni Sassi had the participation of Iris Ceramica consisting of providing temporary outdoor flooring at St. Stephan Square (Piazza Santo Stefano) in Bologna. For this occasion, 10,000 ceramic tiles of 33x33 centimeters were manufactured. Each tile reproduced a healthy soil surface that when assembled together, formed a large "non-polluted artificial field" on the entire square. The Pollution event took place in October ( from 8th until 14th), and it was organized by Carlo Burkhart, who called 24 artists and 2 music bands to occupy and "pollute" the whole square with art and music.

Collection: Tanagra (Iris)

With this collection, Iris Ceramica combined the brand image with a very elegant style. This product was created to fulfill a high quality and luxurious segment of the market. It was a very precious kind of tile with a sophisticated design and aesthetically well-finished but more importantly capable of lasting over time. The sculptor and designer Lodovico Asirelli signed the collection which was inspired by Greek decorations.

Hoffmann Kilns

In 1858, Friedrich Hoffmann patented his first round circular kiln by placing the fireplace near the kiln. Hoffmann kilns are the most common type of kiln. It consists of a main fire passage surrounded on each side by several small rooms, each room is connected by a passageway providing efficient use of heat and fuel. This process is used in production of bricks and ceramic products, and it’s also known as the Hoffmann continuous kiln.

Background and History

Iris Ceramica, Ariostea and GranitiFiandre were established in 1961 and successfully entered the market in a very important and intense period of entrepreneurship in the provinces of Reggio Emilia and Modena.

It was an outstanding period for the Italian economic development, also considered to be an economic boom for the construction sector and entire neighborhoods of popular houses were built. In Italy, the three years from 1959 until 1962 were considered to be the time in which the rates of income growth reached record numbers.

Under these circumstances, the industrialization of the ceramic industry in these regions would have become, within a few years, a worldwide phenomenon due to the multiplication of small and medium-sized companies that have built the foundations for what would later be called “The Tile Valley".

Before 1951, there were only small companies operating in the town of Sassuolo. At the time, the main 11 companies had 3,000 employees. It was also a period considered to be the first years of the industrialization process from 1957 until 1958. As a result of industrialization and expansion, when Iris, Ariostea and Flanders were created, the number of companies were 53 and had 8,500 workers with a production capacity of 365,000 tons per year.

A massive improvement when compared to 54,000 tons per year from 1951.

In the mid-sixties, 40% of the total ceramic production in the European Economic Community (less than 400 thousand square meters per year) was manufactured in Sassuolo.

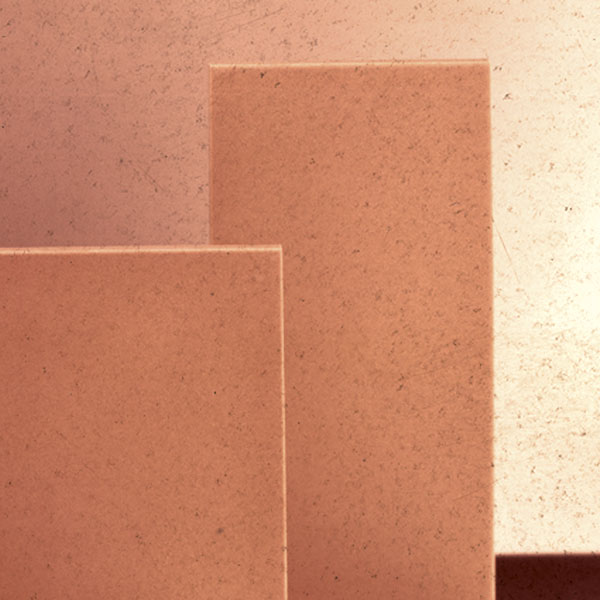

Collection Plain Colors - Flamed Tiles (CCC - Castellarano Ceramics Strong Terracotta)

The first porcelain stoneware floor collection in the provinces of Reggio Emilia and Modena. A choice against all odds, considering that during the seventies the porcelain stoneware was recognized as a high resistant product and therefore singular.

Collection: Roma (Iris)

Launched in 1969, it was a very successful product for several years thanks to its innovative design and color solutions.

In 1968, Romano Minozzi decided to broaden the company’s horizons: The company started exporting to other markets at first in Germany, France, and after a short time all over the European Common Market (MEC) This first step was definitely important to understand the investments required to expand the business participation in foreign markets. So, the creation of the "Consorzio Gruppo Ceramiche Iris" meaning Corporate Ceramics Iris Group combines seven companies together creating new businesses practices sharing similar business approaches suitable to the different markets targeted. The test is positive and within a few years Iris Ceramica would sell 60% of its production to foreign markets.

Collection: Sofia (Iris)

The beginning of a “fashionable story”.

When the tile named "Sofia" started to be created, it was already a seed of the philosophy behind Iris Ceramica.

How did everything start?

When Iris was first established in a region known as "the Sassolese" (between Sassuolo and Fiorano), the production was only about small red ceramic tiles that were glazed with many memorable colors such as the light blue which immediately became recognizable as “Blue Iris”.

In 1961, the production of the CCC (Ceramica Castellarano Cotto Rosso Forte) which means Castellarano Ceramics Strong Terracotta, started in a city called Castellarano. It was mainly concentrated in a type of earthenware, a clay-based unglazed tile, ready to be glazed and subsequently resold to other businesses who were specialized in ceramic glazing techniques. In that period of time, the terracotta tiles were very fashionable. So, that’s how Fiandre was created.

The Ariostea plant was created in 1961, located in the city center of Roteglia. The plant started to manufacture ceramic tiles in 10x10 centimeters, 7,5x15 centimeters, rectangular and 10x20 centimeters in hexagonal shape. The tiles were produced with red clay from the region of Reggio Emilia. Ariostea tiles were used as indoor and outdoor floorings and were produced in tunnel furnaces with cycles of 30-40 hours. As a result, this process allowed the tile to be frost resistant.

From an employee

to an entrepreneur

"When I attended classes in Economics, like all the students, I started to dream about earning money with a new business so I’ve constantly asked myself: “What should I do?”.

At that time, I was little more than twenty years old and I found myself already thinking about a company so my choice went completely in that direction. I’ve wondered about having a constructive gene in my DNA because I felt an natural desire to build something on my own.

But then, after leaving the University of Bologna, I started working for a Commercial Bank.

It was an opposite choice, nothing connected to tiles. So shortly after that, I made a career move and readdressed my career towards the tile industry.

“My career is indissolubly tied to tiles and everything connected to this sector.” Romano Minozzi Iris Ceramica Founder

The 2000s

The two-thousands was considered to be a decade marked by growth of the Internet, which contributed to globalization and allowed faster communication among people around the world.

For Iris Group these were remarkable years of GranitiFiandre being on the stock market board, also years of business debuts such as the StonePeak Ceramics in the U.S. market, Porcelaingres in Germany and Eiffelgres in Italy.

Romano Minozzi’s considered to be an essential and important financial advisor, in view of the fact that he has done everything to set Iris Group in the correct path. Qualifications were always essential, but the role of a professional like Minozzi demands a much broader range of knowledge and skills such as professionalism, expertise, reliability, responsibility, values, a continual pursuit of excellence and leadership. He has worked since his first years, right after graduation as an employee at the Commercial Bank in Modena. As a result of this background, his competence and knowledge of financial markets have often played a big role in his decisions.

GranitiFiandre has operated on the Stock Market board for 10 years, from 2001 until March 2011 due to Minozzi's decision on a takeover bid, so he could combine GranitiFiandre and Iris Ceramica. That was also explained in the newspaper article below:

The Sole 24 Ore Radiocor - Milan, 15 December 2010

GranitiFiandre's major shareholder, Romano Minozzi, has made a takeover bid on the capital of the company, in which he already controlled 68.5%. This offer was made to allow delisting to happen, so GranitiFiandre could be integrated with Iris Ceramica, also owned by Minozzi. The companies involved in this operaton are Mediobanca, the law firm Samori and Modena’s partners.

Floornature.com was created by Romano Minozzi in 2001 to be a portal for information and documentation on how fast changes are happening in the international architectural and design markets. The website Floornature.com is pretty straightforward and clean, but yet complete and innovative. It has become a valuable choice and relevant media, as a web magazine specially for interior designers, professionals and companies.

The Granitech division was established in 2000 to meet the new market demand for turn-key systems and for the provision of customized services. It was born with a precise mission: the design and installation of ventilated walls and raised floors. Granitech proposes many innovative systems and it has been able to develop high-level solutions for major achievements in contemporary architecture. The biggest example of its success is the fact that porcelain stoneware slabs can be used for both horizontal and vertical applications and can be combined with different kinds of material such as steel and aluminum in both floating floors and ventilated walls. Furthermore, innovative solutions have also been developed for floating floors.

Extreme Press

The Extreme press, inaugurated at the Castellarano plant, is able to produce giant porcelain tiles: 150x75 centimeters.

GranitiFiandre was a partner of the Italian General Committee for Expo 2010.

The Pavilion Italy at Expo of Shanghai (China) displayed flooring and wall coatings such as the porcelain stoneware slab XL 120 Anthracite Ground manufactured by GranitiFiandre.

Active Clean Air & Antibacterial Ceramic™

Fiandre, Iris Ceramica and FMG Fabbrica Marmi e Graniti, have improved a new production method in their research and innovation activity, geared to materials with an active ingredient that helps to improve the environmental quality. This production method makes possible the production of ceramic materials for floors and walls, and they are able to make a concrete antibacterial action and they lead to a reduction of pollutants, which unfortunately are a constant in the current urban condition. The collection ACTIVE Clean Air & Antibacterial Ceramic TM can be laid, both in the indoor and outdoor environments of buildings, materials that actively and permanently contribute to a better environment. 1) Bactericidal Effect : The strong oxidizing power of the ACTIVE Clean Air & Antibacterial Ceramic™ photocatalytic action is able to remove the bacteria, some of which are very dangerous for the humans. Photocatalysis does not really kill the bacteria but it decomposes them, irretrievably damaging their cells and causing their death. ACTIVE Clean Air & Antibacterial Ceramic™ removes 100% of these bacterial strains. 2) Self-cleaning Properties : The photocatalytic activity of the TiO2 of the ACTIVE Clean Air & Antibacterial Ceramic™ tiles exerts a dual effect on the daily dirt on the floors and walls (powder, organic residues, etc.) So, the dirt removal is easier and the use of detergents is reduced. 3) Anti-odor Efficiency : Another characteristic is that ACTIVE Clean Air & Antibacterial Ceramic™ is able to degrade the most common organic molecules that cause the smell. 4) Effectiveness against NOx : The photocatalytic process due to the TiO2 deposited on the ACTIVE Clean Air & Antibacterial Ceramic™ tiles destroys and transforms a lot of pollutants and toxic substances in harmless compounds such as nitrates, sulfates and carbonates.

MA.DE and Compasso d'oro (Gold Compass) The collections of Iris Ceramica MA.DE and BRILLIANT compete for the XXI edition of the Compasso d'oro.

SpazioFMG & New Techniques

Iris Ceramica and FMG Fabbrica Marmi e Graniti’s gallery and showroom lauched a new, bigger, more complex layout with completely new design and interiors. Opened in 2007 at Via Bergognone 27 in Milan, SpazioFMG is the place where architecture meets the city, where professionals from all over the world meet to talk about current issues in the discipline and in society. Ever since it was first conceived, on the basis of the convictions and philosophy of the Iris Ceramica and FMG Fabbrica Marmi e Graniti brands, SpazioFMG per l’architettura has declared its mission of promoting awareness of issues related to environmental sustainability in the trade and among the public, with the aim of making complex concepts, methods and synergies a common heritage. With this background, the gallery also became the home of the Floornature.com architecture portal, allowing ideas and suggestions received locally to be merged with those received over the internet and through the new media. The gallery’s new exhibition layout underlines this point of arrival and the opening of new exhibition projects in collaboration with Floornature.com.

Collection: Legni High Tech (Wood) (Ariostea)

High tech woods faithfully reproduce the look, tactile feeling, and veins of natural wood. A product so close to perfection, manufactured without touching a leaf. Its large listels are unique, this is the best way to appreciate the uniqueness of these products. You can feel the warmth and structure of wood; Ariostea has combined these natural qualities, in a ceramic wood tile, with technical characteristics that make these products more resistant to deep abrasion, water, heat, chemical agents. They do not require any treatment before or after installation or in the following years. They offer the visual impact of wood porcelain tiles with the strength of stone: compact tiles of ultra-fine solid porcelain stoneware reconciling the strip design of top quality natural parquet with the need for strength in today's interiors. Ariostea presented vintage oak slabs in the large size of 150 centimeters.

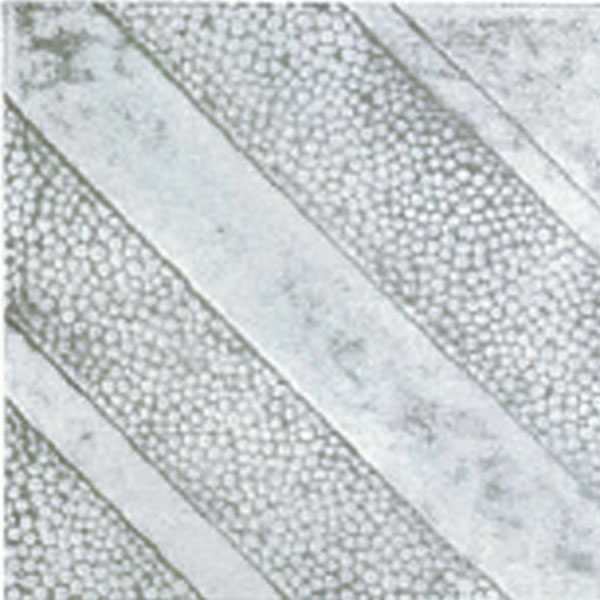

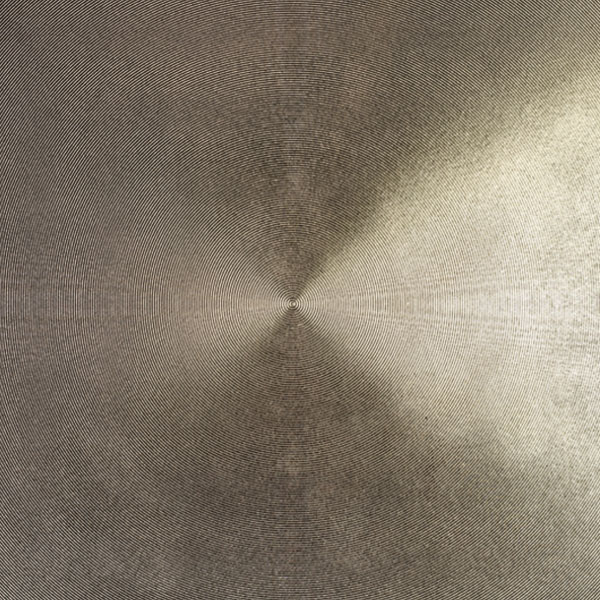

Collection: Luminar (GranitiFiandre)

The Luminar collection brought together different fields of knowledge, the "warp" of technology and the "woof" of a cultural background that draws on several sectors to craft the excellence of GranitiFiandre. Moreover, Luminar went beyond the classic effects of light found in nature because it offered an innovative solution where matter lets itself be shaped by light, creating a beautiful shimmer no matter what the conditions are: in full light, in shadow, and even in moonlight. The surface of the material is covered by a continuous series of concentric circular engravings: the result is a bright, reflective surface, created in part through a special treatment that is applied to the technical porcelain stoneware to ensure outstanding aesthetic results. Luminar got its visual impact from the unique optical effect given by its surface design. It’s an interactive material that plays with light, is born of light, reflects light, and generates light. The range of colors OptoWhite, OptoBlack, OptoGold, OptoSilver and OptoBronze.

Collection: MA.DE (Iris Ceramica)

Ceramic preciousness with a new name: MA.DE. New colors, new surfaces and a new size: the 120x60 centimeters, to once again enhance the textures and attractiveness of the collection. The “MA.DE” collection has received the most important international awards: the first ceramic tile in ADI Design Index 2006, the Guide for the Industrial Design Association.

Collection: GeoDiamond (Fiandre)

After the the acquisition of Hydrodesign, GranitiFiandre began to experiment with materials: cut and adjusted according to new shapes and geometric forms rich in ideas to create new concepts of interior design. In the GeoDiamond collection, the metal blends for the first time with the coloured-in body porcelain stoneware.

Collection: Pietra d'Aragona e Pietra di Brera (Eiffelgres)

The evolution towards perfection is unstoppable and in 2006 Eiffelgres surprised everyone with the collections Pietra d’Aragona meaning Aragon Stone and Pietra di Brera meaning Brera Stone. The Pietra d’Aragona collection, was inspired by the most delicate limestone, a product of an innovative hi-tech productive process perfected in Eiffelgres’s research laboratories which makes it possible to obtain the randomness that was in the past the exclusive prerogative of natural quarried stones. Every slab in the Pietra d’Aragona collection is unique and unrepeatable, perfect for surrounding you with a feeling of softness to create an elegant, refined setting. In Pietra d’Aragona, Eiffelgres combines the aesthetics and naturalness of quarried stone with the high performance of hi-tech porcelain stoneware. Also, the Pietra di Brera collection was a product of Eiffelgres researchers’ ongoing interaction with the engineers and architects who are redesigning the world’s cities and building large-scale public spaces and housing developments.

After the investment in Germany, it was time for the biggest step ever: The acquisition of a company called Crossville in Tennessee - United States. A big dream of Romano Minozzi, who planned, along with the creation of the StonePeak Ceramics brand to manufacture beautiful, sustainable solutions that advance the frontiers of tile design. From introducing the nation’s first large-format porcelain tiles, to becoming the first and only net consumer of tile waste materials, to developing cutting-edge performance innovations that turn surfaces into “breathing” living environments. Moreover, the company is committed to develop pioneering products and practices that change the way the world views tile.

Collection: Limestone (Stonepeak Ceramics)

Subtle organic beauty marks StonePeak's unglazed porcelain limestone. This line features the thru-body color variations and dimensionality of real limestone, while delivering precisely squared corners and greater durability than natural stone. And like real limestone, no two StonePeak Limestone tiles are alike. This series comes with a full range of complementary trims and is ideally matched for commercial and residential settings such as hotels, hospitals, airports, shopping malls, libraries, and in residential flooring, walls, patios, walkways and more.